When it comes to processing equipment like mixers, sifters and screeners, it’s often not a question of if, but when a crucial component will start to wear out.

The impact of downtime can be substantial, eating up 1-10% of production time, according to Processing Magazine. Overall, downtime costs industrial manufacturers as much as $50 billion a year.

To avoid dips in equipment performance and repairs that result in costly downtime, you’ll want to keep a few key replacement parts in stock. Here are four common parts that should be in the storage room of any facility:

- Bearings By some estimates, up to 60% of equipment breakdowns in a facility involve bearing wear, so having replacement bearings in stock is crucial. As a wearable part, there are many factors that may cause a bearing to fail including design, quality, storage and handling, installation and alignment, and lubrication.

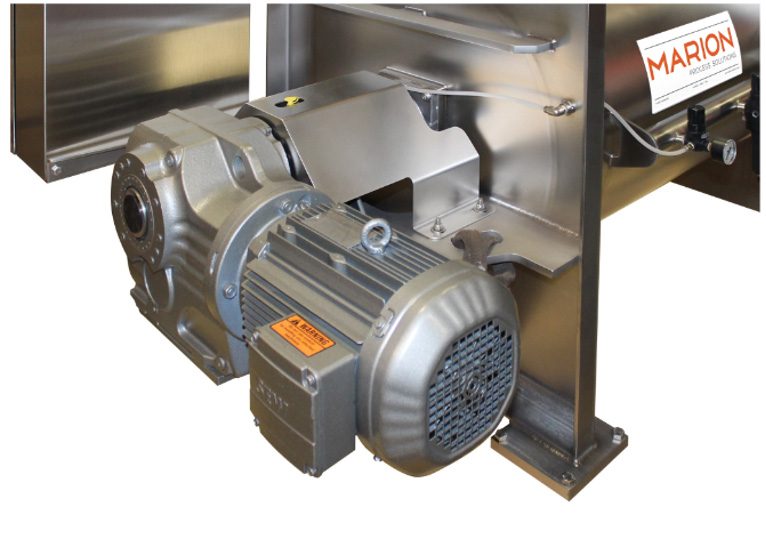

- Motors Even if you never experience a motor failure, the cost of downtime alone is worth having a spare motor. Power quality, excessive loads, misalignment with the motor drive shaft and bearing wear are among the factors that can lead to a motor failure, which can bring production (and revenue) to a halt.

- Gearboxes Some of the most common forms of gearbox failure include under or over lubrication, using the wrong lubricant by mistake and contamination. Gear misalignment and overloading are other potential issues that can cause premature wear and tear. Because the chances a failing gearbox will stop production are more than likely, it’s wise to add extra gearboxes to your parts inventory.

- Screens Screens used for sifting/separating chemicals, pharmaceuticals, foods, minerals and other powders and granules take a lot of abuse. While they are built to handle a wide array of materials (including those with corrosive qualities), 90% of the time screens fail due to screen fatigue. Rapid and repeated flexing of screen mesh and an accumulation of material around the outside edges of the screen are some causes of screen fatigue.

The four parts covered above can quite literally mean the difference between a simple repair and an unplanned emergency. If you can quickly access these parts, you’ll be in an ideal position to keep your equipment in good working order. If not, then you’ll be counting the lost production hours – and profits – until the part gets delivered to your door and installed.

Want more education on servicing processing equipment?

Check out these resources: